Power plants generated through wind energy in India have witnessed a significant transformation over the last 5 years. Currently, India holds the 4th largest installed wind power capacity globally. To ensure the availability of clean energy at all times, diversifying the various sources of energy generation is key to this transformation journey. And wind energy is one of the ways to do so. By 2030, the majority of Indian states plan to contract wind energy in their energy supply mix.

However, just like any mechanical device, a wind turbine also requires regular maintenance and upkeep inspections to ensure optimal performance and longevity of the parts. Proper upkeep can help prevent costly repairs, sudden breakdowns, and malfunctions, thereby extending the lifespan of turbines and their overall efficiency.

Regular upkeep and timely maintenance of the wind farm are necessary so that:

· Highest efficiency and optimal performance: A well-repaired and maintained turbine will give optimum production and run effortlessly.

· Extended life of the farm and its parts: Regular care and upkeep help extend the life span of all the parts and machinery, thereby providing better return on initial investment.

· Cost Savings: With regular maintenance, small repairs and touch-ups can be recognised and dealt with first-hand as opposed to turbine failures. Oversight and negligence can cause a lot of damage and expense in the case of wind farms.

Regular maintenance plays a crucial role in ensuring optimal wind turbine performance and maximizing energy generation. Adhering to scheduled maintenance timelines helps extend the lifespan of turbines, rejuvenate existing equipment, and maintain long-term competitiveness in the market. For larger turbines, comprehensive maintenance involves routine inspections, performance monitoring, and timely repairs to prevent long-term damage. In addition, continuous data analysis and monitoring enable operators to optimize efficiency, identify irregularities, and quickly address potential issues before they escalate.

1. Turbine Blade Maintenance: The turbine blade (rotor blade) is largely responsible for capturing wind from open airspace and converting it into rotational motion for the generation of energy. Hence, it’s a critical point area of the wind energy generation process and should always be checked and kept in the best condition, so that it can perform to the best of its capabilities.

2. Brake System (Yaw): The yaw is responsible for rotating the turbine and facing the wind. They are an essential component in guiding the direction of the turbine. Regular lubrication of the brake system is critical in keeping the system functions running smoothly. Additionally, wind turbines can have up to 20 yaw brakes facing the correct direction relative to the wind, and if one of these suffers damage or requires replacement, it requires a lot of time for replacement and to fix the brakes.

3. Gearbox: The role of the gearbox cannot be understated in producing wind energy. Gearbox is responsible for transmitting low-speed kinetic energy into high-speed energy through the increased rotor movement of the blade, to match the generator’s speed. It is critical to check the lubrication of the gearbox, if any leaks are present in the motor, oil levels, and any wear and tear. The gearbox failure leads to increased downtime of the turbine, affecting the production of wind energy.

4. Generator: Known to be the heartbeat of the entire process of wind generation. The generator is responsible for converting the energy of wind into electricity by rotating the shaft. Ensuring proper alignment of all parts, lubrication, motor failures, etc., has to be checked thoroughly to ensure their smooth functioning and to prevent any failures.

5. Wiring, consisting of the entire Electrical System: The control unit or the electrical system that consists of wires, monitors, earthing, control panels, digital systems etc needs to be inspected regularly. This is mainly to ensure durable cables are utilized so that the system can withstand vibrations and bad weather.

The cost incurred for the maintenance and upkeep of turbines depends totally on the day-to-day maintenance, how efficiently its upkeep is conducted to avoid any wear and tear of the turbines. For instance, a 1 MW wind turbine project with a capital cost of ₹4.5 to ₹6.5 crore would have an estimated annual O&M cost of 1-2% of the capital investment.

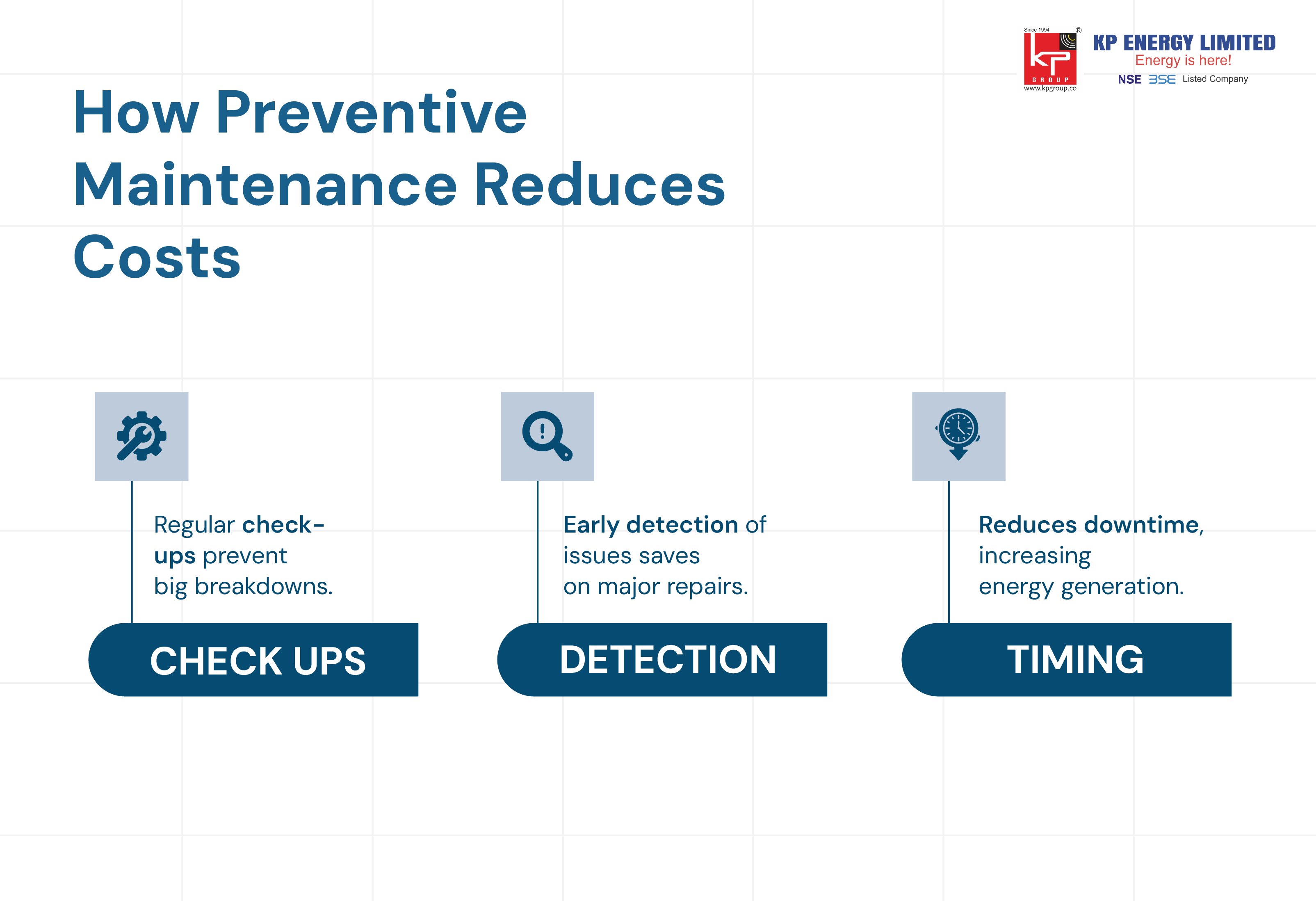

It is very critical in today’s time to factor in the maintenance and upkeep cost while setting budgets and realizing the price value of the generated energy. The cost of maintaining wind turbines could be reduced if one studies the exact condition of the wind turbines and analyzes the data systematically. Preventive maintenance of wind turbines are an approach of maintaining wind turbines by taking the support of other technologies to study beforehand any upcoming potential causes of failures, breakdowns, or possible concerns to avoid any last-minute crisis, escalation, or shutdown.

It further saves individuals from having to spend on extensive repairs and replacements, as it pushes the idea of regular maintenance and repairs, thereby avoiding any unplanned shutdown, which would increase the opportunity cost of not generating power during downtime.

Additionally, with regular upkeep and scheduled maintenance of the turbines, it helps extend the life span of the turbine and its parts.

On-shore wind turbines are generated by turbines located on green land, where the turbines respond to the natural air speed. An offshore wind turbine, on the other hand, is generated from the winds that blow across the shoreline. In comparison, offshore winds have a greater capacity to generate electricity when compared to on-shore wind farms, due to the high speed of winds and lack of any structural interface, tall trees, or objects. Offshore wind farms, due to their very nature, which demands presence close to the water body and or on top of the marine surface, require expensive floating components, cables that can be present under water, specialized equipment that can be water resistant, etc. Additionally, offshore turbines face unpredictable weather conditions, making their maintenance even more critical. All of these factors make the upkeep and maintenance of the offshore wind farms more expensive when compared to onshore.

The importance of proactive maintenance checks and timely inspections will grow as wind energy evolves. KP Energy’s wind projects, both onshore and offshore, have been designed and built for decades now. Capitalizing on the vast experiences and evolving landscape, teaming up with dependable service providers such as us will help you unlock your full potential towards becoming sustainable in the clean energy space. With expert wind turbine operation maintenance, you can maximize efficiency, reduce downtime, and extend turbine life.

Maximize wind asset value with KP Energy's proven maintenance & optimization services

Q1: How is wind energy generated?

Wind energy is a clean source of energy generation, which transitions itself from the kinetic energy of the wind into mechanical energy, which is converted into electrical energy.

Q2: What are the environmental benefits of wind energy?

Wind energy is a clean and renewable source of energy that provides independence from non-renewable sources, which helps reduce greenhouse emissions.

Q3: What is an offshore wind turbine?

An offshore wind turbine is generated from the winds that blow across the shoreline.