Wind energy is rapidly becoming a major contributor to India’s green future. As we strive to decrease our carbon footprint and generate sustainable power to run our industries, wind energy systems appear to be a stable and dependable source. However, how does the system work? What components are included in a wind energy conversion system that make it capable of generating clean power?

This article will summarize the basic structure of wind energy system, while identifying and outlining each important component that makes type wind power generation system. These components range from mechanical gears to intelligent controllers that help in the conversion of energy from wind into a usable source of power.

Let’s understand the parts of a wind turbine system, their roles, and how important they are for the advancement of renewable energy.

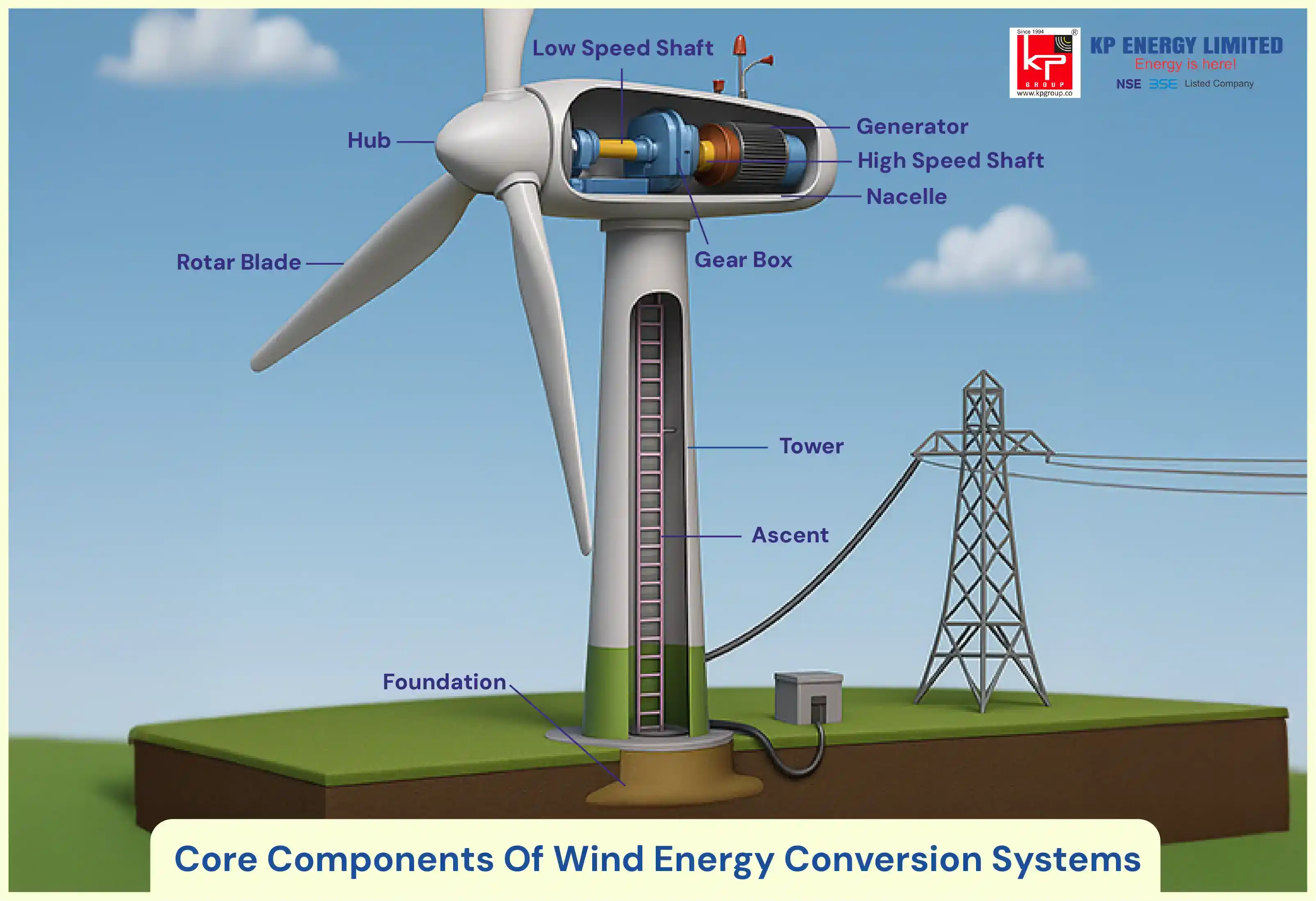

A wind energy conversion system (WECS) includes a combination of the mechanical and electrical components of WECS to capture wind energy and convert it to usable electricity. These installations can include larger wind farms or smaller systems. The conversion process essentially consists of the collection of wind using blades, converting the wind kinetic energy into mechanical energy, and finally, converting mechanical energy into electricity using the generator.

The conversion process is reliant on the overall interaction of a number of wind energy conversion system components, including aerodynamic components of wind turbines, control systems, shafts, gearboxes, and electronics units.

Here are the key wind energy conversion system components that form the backbone of any turbine installation:

The rotor is one of the most important aerodynamic components of a wind turbine. It consists of blades that are connected to a central hub. Wind traveling over the blades creates a lift force, similar to wings on an airplane, causing rotational displacement of the rotor.

Blades: The blades are designed to capture as much wind as possible but are made of fiberglass, occasionally carbon-reinforced plastic, and usually are optimized to capture wind. Many wind turbines use two or three blades.

Hub: This plays a role in adjusting pitch to regulate rotation speed.

Together, these aerodynamic components of wind turbine help in the conversion of wind's kinetic energy into mechanical rotation that starts the power generation process.

Once the rotor spins, the mechanical and electrical components of WECS take over.

Low-Speed Shaft: Transfers the rotational energy from the rotor to the gear box.

Gearbox: Steps up the low-speed rotation (30–60 RPM) to a speed that is appropriate for power generation (1000–1800 RPM).

This combination of mechanical and electrical components of WECS ensures efficient transmission of energy from wind to the generator.

At the heart of every wind power generation system is the generator. This converts mechanical rotation into electrical energy.

Synchronous Generators and Asynchronous Generators are the two main types used.

Generators are connected via a high-speed shaft from the gearbox and form the main part of wind turbine generator components.

These generators are made to produce high-quality, grid-compliant electricity, making them important wind turbine generator components.

The nacelle is a streamline shaped envelope, mounted on the top of the tower that consists of the gearbox, generator, controller, and shafts. The nacelle helps to protect the wind turbine generator components (the gearbox and generator) from the different environmental factors like dust, rain, and extreme temperatures, and reduces the amount of repair and maintenance by providing a compact unit to keep the system safe and operating at its highest level.

The basic structure of wind energy system relies on sturdy towers and solid foundations.

Tower: Raises the turbine to heights where wind speeds are optimal. It also supports the weight of the nacelle and rotor.

Foundation: Customized based on soil and wind conditions. It ensures structural integrity over time.

The wind turbine control system consists of sensors, processors, and actuators that keep a check and manage the turbine’s operations.

Yaw Control: Rotates the nacelle to align with wind direction.

Pitch Control: Adjusts the blade angle in order to optimize power output.

Brake System: Halts operation during high wind speeds or maintenance.

These features demonstrate how wind energy systems work safely and efficiently across various conditions.

The controller acts as the brain of the system. It:

Starts the turbine at a cut-in wind speed (around 3 m/s).

Stops it at cut-out speeds (around 25 m/s).

Manages power flow and component temperatures.

In addition to performance, these units are important for safety, making them key mechanical and electrical components of WECS.

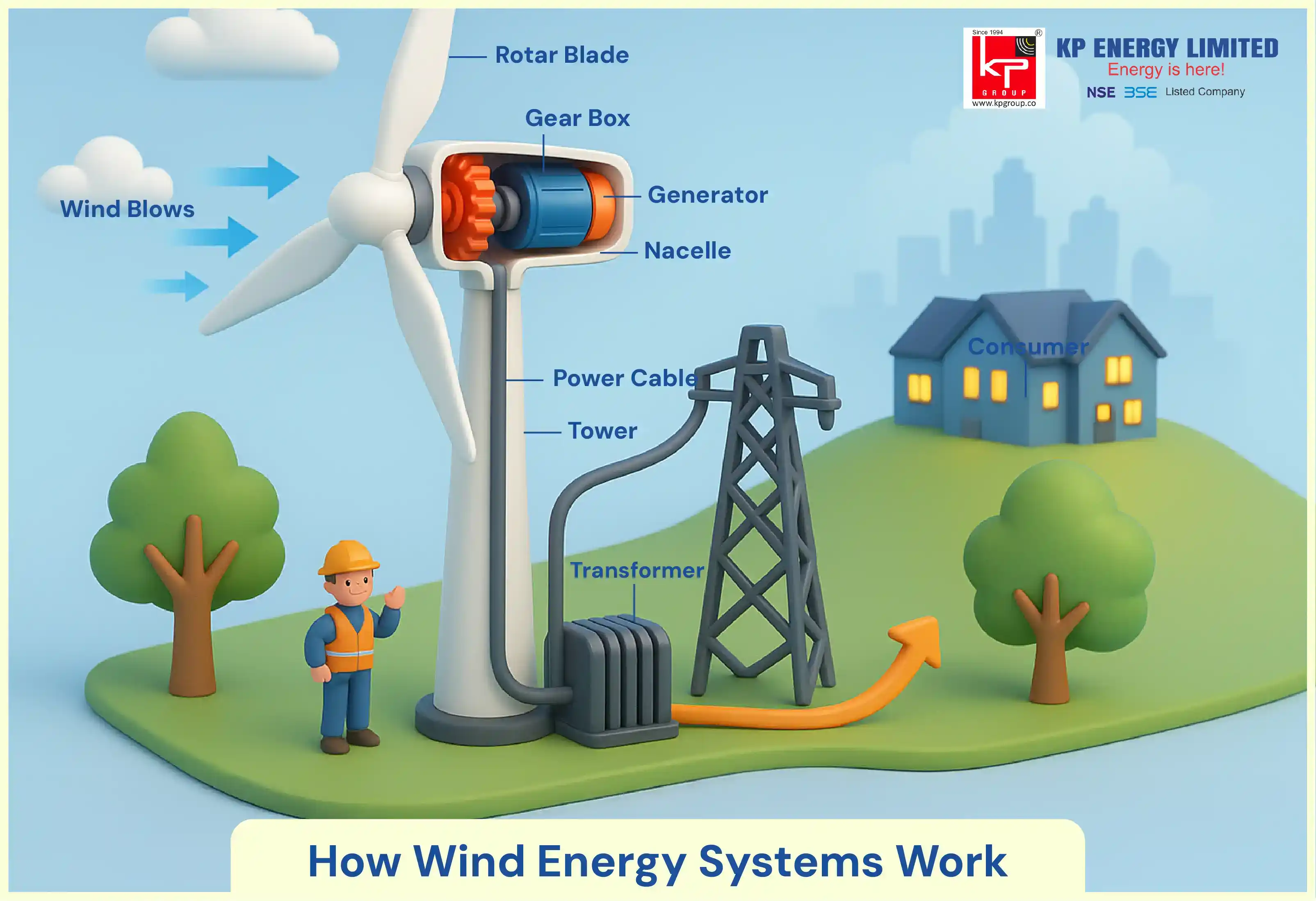

Here’s a basic explanation of how wind energy systems work to turn wind into electricity:

Wind Blows: The wind blows and moves the blades of the turbine.

Blades Turn The Rotor: The spinning blades rotate the rotor and the low-speed shaft.

Speed Increases: The gearbox increases the speed of rotation.

Generator Starts Working: The fast-moving shaft powers the generator.

Electricity Is Made: The generator produces electricity. This power goes to the electric grid or is stored in batteries.

Each stage requires different parts of wind energy conversion system to work together efficiently to produce electricity.

New wind turbines have special tools that make them work better and last longer:

Anemometer: This small device checks how fast the wind is blowing and sends the data to the control system.

Wind Vane: It shows the direction of the wind, helping the turbine turn to face the wind correctly.

Cooling System: Keeps the generator and gearbox from getting too hot while working.

Braking System: Stops the turbine safely in case of an emergency. It uses both air and mechanical brakes.

These features help wind turbines work properly and keep them safe for many years.

Wind turbines stand on tall towers. It depends on the type of tower where the turbine is and how big it is:

Tubular Towers: These are the most common towers. They are strong, quiet, and reduce wind disturbance.

Lattice Towers: These towers look like a metal grid. They are cheaper and lighter than tubular towers.

Guyed Towers: These towers are supported by wires. They are used for small turbines or locations that are far away.

Each tower type has different roles, depending on the land and how strong the wind is in that area.

Designing an effective wind power generation system involves:

Optimizing the number and shape of blades.

Choosing suitable gear and transmission systems.

Integrating electronic controls that enhance safety and power quality.

Selecting appropriate wind turbine generator components for local grid compatibility.

Together, these aspects define how well the wind energy system's working principle functions in real-world conditions.

A deep understanding of the components of the wind energy conversion system helps in:

Reducing downtime with timely maintenance.

Enhancing energy output through smart design.

Scaling installations for grid or off-grid use.

Ensuring cost-efficiency and environmental safety.

As India scales up wind infrastructure, especially through industry leaders like KP Energy, knowing the wind energy conversion system components becomes essential for project success.

KP Energy Limited has expertise in the design, development and operation of wind energy conversion system across India. Our experienced teams manage everything from site selection to assembly of the components and overseeing the wind turbine to be sure it functions as intended and produces optimal power output.

Using precision engineering and optimum component systems, KP Energy helps India transition to sustainable, affordable and reliable energy. Every component from the rotor blades to the wind turbine control system ensures that parts of a wind turbine system work in unison to deliver results.

The reliability of a wind power generation system is reliant on each one of its components. Every item, from the aerodynamic components of wind turbine, to the smart controllers, each has an important role to play in producing clean and productive energy.

When the mechanical and electrical components of WECS are understood, decisions and developments become easier, which tend to lead to a safer and sustainable future.

As KP Energy leads with wind energy capacity in India, we remain focused on quality, innovation and community empowerment. Because when all the components are working in perfect harmony, the future will run on wind.

Q1. What are the important components of a wind energy system?

A. A wind energy system is made up of several interconnected components that work together to capture and convert wind into electricity. The most important parts include the blades, rotor and hub, gearbox, generator, tower, and control system.

Q2. How do mechanical and electrical components work together?

A. Mechanical and electrical components in a wind energy system are designed to function in harmony. The mechanical parts, such as the blades, rotor, and shaft, capture the kinetic energy of the wind and transform it into rotational energy. This rotational force is transmitted through the gearbox to the generator, which belongs to the electrical system.

Q3. What are the aerodynamic characteristics of a wind turbine?

A. The aerodynamic performance of a wind turbine depends primarily on the design of its blades and rotor. Turbine blades are carefully engineered with airfoil-shaped profiles that maximize lift while reducing drag, enabling them to capture more wind energy than their physical size alone would suggest.

Q4. Why is the tower an essential part of the wind energy system?

The tower plays a critical role in the efficiency and stability of a wind turbine. By elevating the rotor and blades high above the ground, the tower allows the turbine to capture stronger and more consistent wind flows, which directly improves energy generation.