Wind energy has emerged as one of the most plentiful renewable energy resources globally. With this, wind turbines have become the leading technology to exploit this renewable resource. Knowing how to calculate wind turbine power output is a critical component for engineers, project developers, and all stakeholders involved in wind energy planning. This information guide will outline the concepts, the equations and provide a step-wise approach to calculate wind turbine power output.

The fundamental formula for wind turbine power is obtained from the kinetic energy of moving air masses. The basic equation for calculating wind power available in the wind is as follows,

P = ½ × ρ × A × V³

Where:

P = Power (watts)

ρ (rho) = Air density (kg/m³)

A = Rotor swept area (m²)

V = Wind speed (m/s)

The equation illustrates the maximum possible energy that can be derived from the wind, but for wind power as a turbine or wind farm output, you need to factor in turbine efficiency and the Betz limit which no wind turbines can achieve more than 59.3 % of the kinetic energy that the wind contains.

Thus, basis the above, the practical formula for wind turbine power output becomes:

P_turbine = ½ × ρ × A × V³ × Cp

Where Cp is the power coefficient, which shows the turbine's efficiency to convert wind energy to electrical energy.

Wind speed is the most important variable in the wind turbine power output calculation. In the previous formula, we see that power output is proportional to the cube of wind speed (V³).

This cubic relationship implies that:

Power output will increase by eight times if the wind speed doubles.

A 10% increase in wind speed will cause approximately 33% more power output; and

Small changes in wind speed will give large changes in energy production.

This cubic relationship explains the importance of wind resource assessment to a successful wind energy project. This is because areas with persistently high wind speeds will generate exponentially more energy than areas with moderate winds.

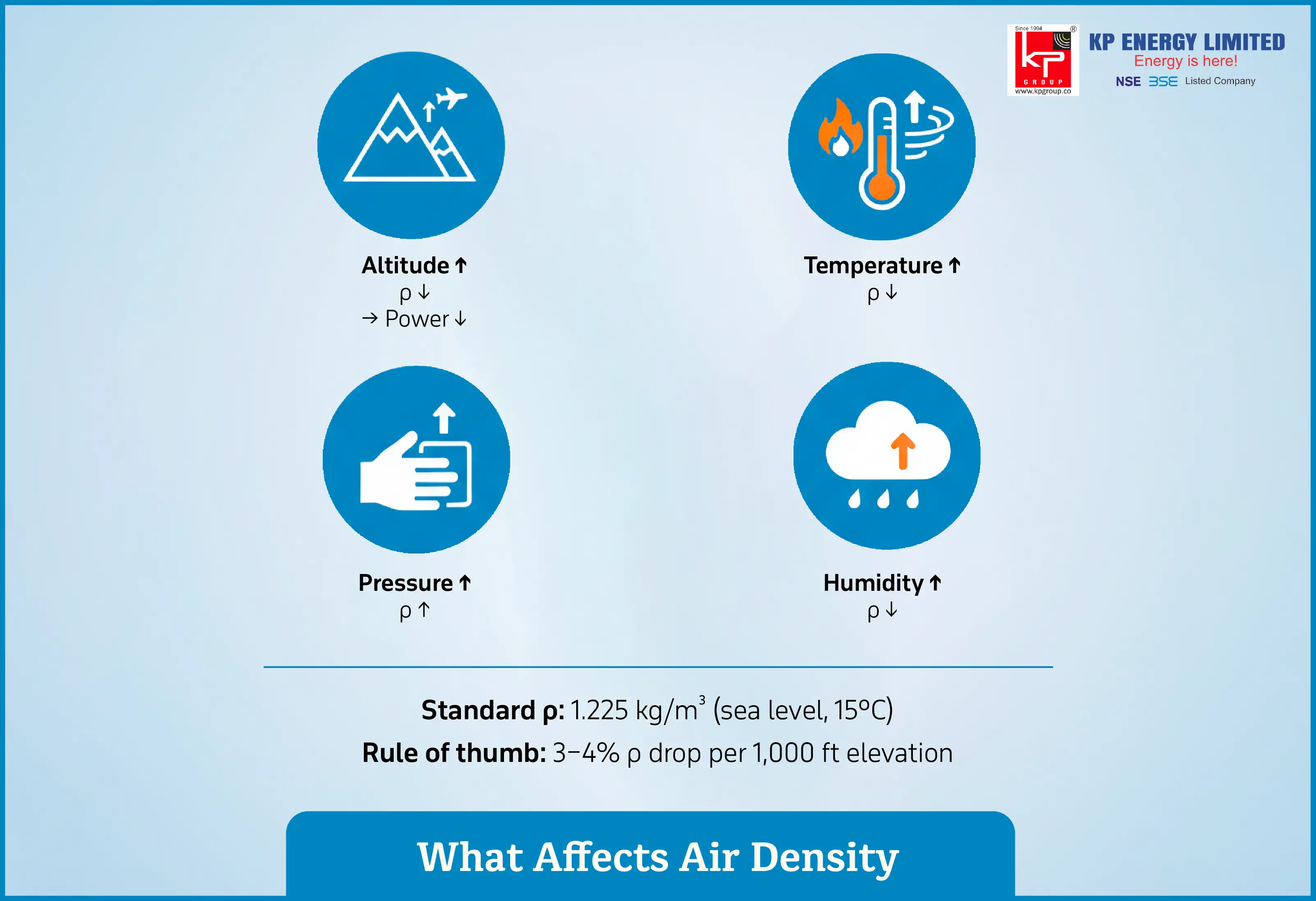

The density of air directly impacts power generation since denser air contains more kinetic energy in a given volume or "unit". There are several factors affecting air density:

Altitude - an increase in altitude means lower air density, which leads to lower power output for your turbine

Temperature - Cold air is denser than warm air.

Atmospheric pressure - An increase in atmospheric pressure will increase air density

Humidity -Humid air has a slightly lower density than dry air

The density of air at standard volume conditions (sea level and 15 degrees C or 59 degrees F) is 1.225 kg/m3. Typically, the density of air decreases by approximately 3 - 4% (from the value measured at sea level) for every increase in elevation of 1,000 ft away from sea level.

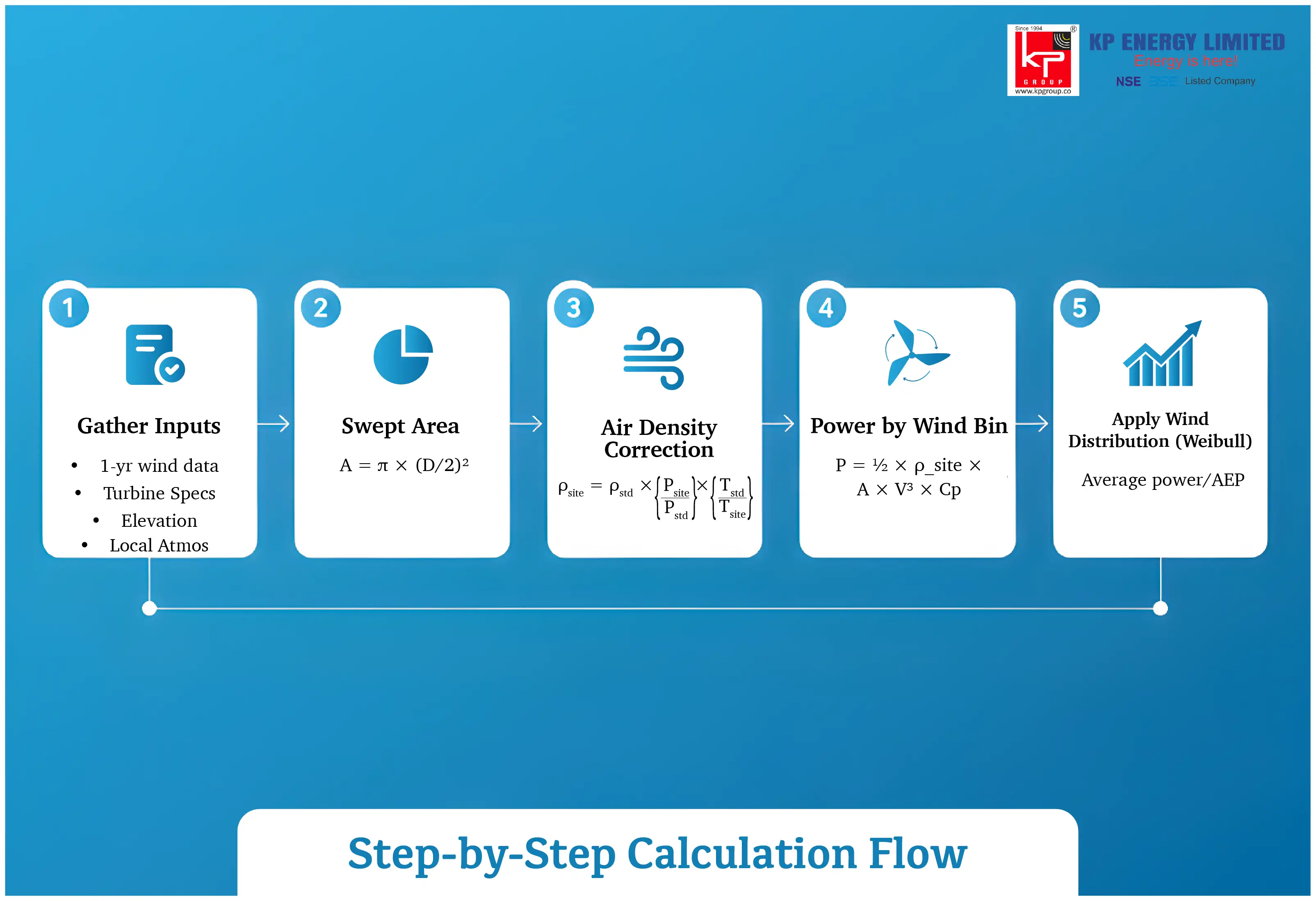

Prior to finding the power output of your wind turbine, you will require:

Wind speed data ( hourly measurements over at least one year)

Wind turbine parameters (power curve, rotor diameter, hub height).

Site elevation and local atmospheric conditions

Air density corrections for the location that has been specified

Calculate the rotor swept area using the turbine's rotor diameter:

A = π × (D/2)²

Where D is the rotor diameter in meters.

For example, a turbine with a 100-meter rotor diameter has a swept area of: A = π × (100/2)² = π × 50² = 7,854 m²

Adjust the standard air density for your specific location:

ρ_site = ρ_standard × (P_site/P_standard) × (T_standard/T_site)

Where:

P = atmospheric pressure

T = absolute temperature in Kelvin

Using the corrected values, calculate power output across the wind speed range:

P = ½ × ρ_site × A × V³ × Cp

Create a power curve showing output versus wind speed, typically from cut-in speed (3-4 m/s) to cut-out speed (20-25 m/s).

Use the site's wind speed frequency distribution (often modeled using Weibull distribution) to weight the power calculations and determine average power output.

The rotor swept area is fundamental to wind turbine power output calculation as it determines how much wind the turbine can capture. Key aspects include:

The amount of power output is proportional to the rotation swept area with the rotor diameter being doubled increasing the swept area by four times which means four times the power output for the same wind speed..

Modern wind turbines maximize swept area while optimizing structure:

Larger rotors collects more wind

Optimized blade design increases aerodynamic efficiency

Variable pitch control keeps optimal angle of attack

The effective use of rotor swept area depends on:

Wind shear (wind speed variation with height)

Turbulence intensity affecting energy extraction

Wake effects from nearby turbines

Several environmental conditions significantly impact estimating wind energy production:

Seasonal variations in wind patterns and air density

Diurnal cycles affecting wind speed and direction

Weather fronts creating temporary high or low wind periods

Terrain effects causing acceleration or turbulence

Turbine design and operational parameters influence calculating wind power efficiency:

Power coefficient (Cp) varies with wind speed and blade pitch angle

Generator efficiency affects conversion of mechanical to electrical power

Transmission losses reduce delivered power

Maintenance downtime impacts annual availability

Real-world conditions affect theoretical calculations:

Grid curtailment may limit power delivery during high production periods

Ice formation can stop turbines in cold climates

Environmental restrictions may require seasonal shutdowns

Component wear gradually reduces efficiency over time

Estimating wind energy production annually requires integrating instantaneous power calculations over time:

AEP = Σ(P_i × f_i × 8,760)

Where:

P_i = Power output at wind speed bin i

f_i = Frequency of wind speed bin i

8,760 = Hours per year

The wind turbine capacity factor represents the ratio of actual energy production to theoretical maximum production:

Capacity Factor = (Actual AEP) / (Rated Power × 8,760 hours) × 100%

Typical capacity factors range from:

Onshore turbines: 25-45%

Offshore turbines: 35-55%

Wind turbines create wake zones downstream, reducing wind speeds for neighboring turbines. Wake modeling requires:

Wake deficit calculations using models like Jensen or Frandsen

Array layout optimization to minimize wake losses

Directional considerations accounting for prevailing wind patterns

High turbulence intensity affects power production through:

Reduced energy extraction efficiency

Increased fatigue loading on components

Variable power output creates grid integration challenges

High-altitude installations require specific adjustments:

Air density corrections for elevation

Temperature lapse rate considerations

Pressure altitude effects on turbine performance

Large-scale wind projects require comprehensive wind turbine power output calculations, including:

Detailed wind resource assessment using meteorological towers.

Mesoscale modeling for regional wind pattern analysis.

Micrositing studies optimizing individual turbine placement.

Financial modeling incorporating capacity factor projections.

Residential and small commercial installations need simplified approaches:

Simplified wind resource estimation using available databases.

Basic power calculations for initial feasibility.

Economic analysis considering local electricity rates.

Permitting considerations for smaller turbines.

Q1: What Is The Most Important Factor In Wind Turbine Power Output?

Wind speed is the primary determining factor due to the cubic relationship between wind speed and power output. Even small increases in average wind speed substantially improve energy generation and project economics.

Q2: How Accurate Are Wind Turbine Power Calculations?

Professional wind assessments will achieve 5-10% accuracy to estimate annual energy production on average during most days using proper measurement campaigns or more advanced modelling. The accuracy mainly depends on the quality of wind data collected, as well as the quality of analysis that can be performed or modelled.

Q3: Why Do Actual Power Outputs Differ From Calculated Values?

Actual power production values vary from calculated ones due to real-world conditions such as wake effects, turbulent conditions, grid curtailment, downtime for maintenance, and environmental conditions. Annual production can also be influenced by longer-term variations in wind speed.

Q4: How Often Should Wind Turbine Power Calculations Be Updated?

For major changes like turbine upgrades or new environments, and where multi-year operational data is used, the power calculation should be recalculated.

Q5: What Role Does Temperature Play In Wind Turbine Efficiency?

Temperature affects air density and therefore affects power output. Colder air is denser and has more energy, but freezing temperatures create ice which leads to a shutdown. Most newer turbines allow for temperature adjustment as part of the power curve.

Q6: Can Small Wind Turbines Use The Same Calculation Methods?

The fundamental physics are the same, but small wind turbines are more subject to more variable wind conditions and have higher turbulence intensity. Simplified calculation methods may work for initial screening calculations, but detailed calculations must also consider small turbine-specific factors.