Wind turbines are extraordinary engineering feats, created to take advantage of wind energy and use it to generate clean and renewable energy. However, as with all mechanical systems, they face challenges in their operation that require complex safety features. Important to wind turbine operation, is wind turbine overspeed protection, which is a sophisticated system that is installed to protect from dangerous situations when turbines overspeed and exceed their safe operating criteria.

Modern wind farms have integrated wind turbine safety systems as crucial elements to protect equipment long-term and to protect the safety of wind operations. These systems, when wind conditions become excessive, need to protect the wind towers from potentially damaging situations in the turbines (rotors that are spinning too quickly).

Multiple dangers may occur due to a wind turbine exceeding its design rotation speed. The effects of uncontrolled overspeed conditions go well beyond simple wear and result in a failure that could lead to the destruction of equipment and a threat to personnel safety.

Excessive rotational speed creates enormous centrifugal forces that can exceed the structural limits of turbine components. The rotor blades, which are engineered to withstand specific stress levels, may experience:

Blade tip speeds that exceed material tolerance limits.

Increased vibrations that can damage the nacelle and tower structure.

Bearing wear that accelerates exponentially with speed increases.

Gearbox components are experiencing forces beyond their design parameters.

When turbines spin too fast, the generator produces electricity at frequencies and voltages that can damage electrical components. This can result in:

Power inverter failures due to excessive input voltage.

Grid connection issues that may trip protective relays.

Transformer damage from voltage spikes.

Control system malfunctions caused by electrical interference.

At excessive speeds, wind turbine blades can enter aerodynamic stall conditions that create unpredictable forces. This phenomenon can cause:

Sudden load changes that stress the entire drivetrain.

Blade flutter that may lead to structural failure.

Tower oscillations that compromise foundation stability.

Noise levels that exceed environmental regulations.

Today's wind turbines have multiple turbine overspeed control systems in place to provide layers of protection from unsafe operating conditions. This will result in a variety of sophisticated protection mechanisms being in place that will share the work of providing safe operation in all wind conditions.

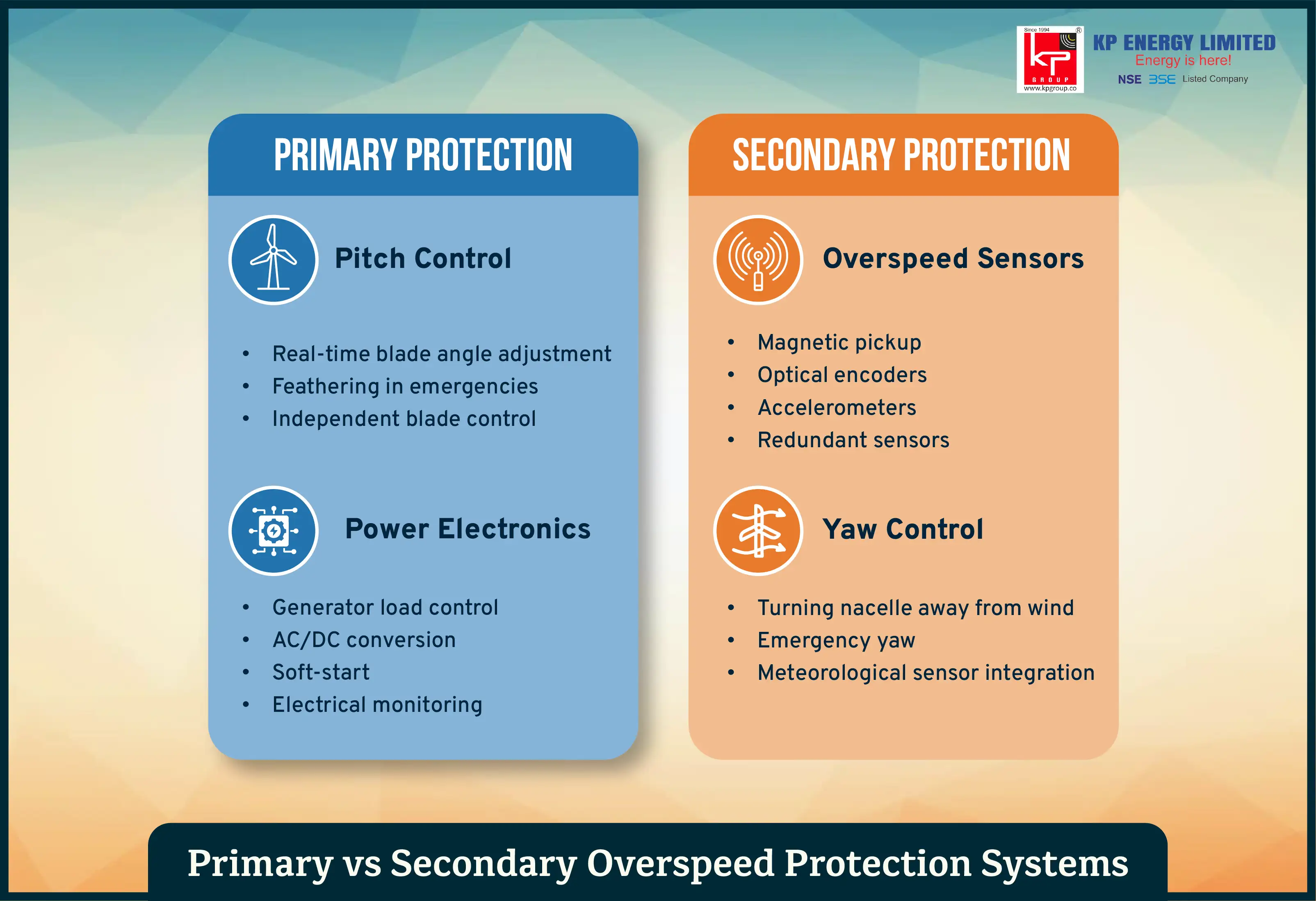

The first line of defense against overspeed conditions involves active control systems that continuously monitor and adjust turbine operation:

Pitch control systems represent the most effective method of managing turbine speed. These systems can:

Adjust blade angles in real-time to reduce aerodynamic efficiency

Respond to speed increases within seconds

Feather blades completely during emergency conditions

Operate independently for each blade to maintain balance

Advanced power electronics provide precise control over generator speed by:

Adjusting generator load to maintain optimal rotor speed

Converting variable AC output to grid-compatible electricity

Implementing soft-start procedures during wind-up conditions

Monitoring electrical parameters for abnormal conditions

When primary systems cannot maintain safe speeds, secondary protection mechanisms activate automatically:

Modern turbines incorporate multiple speed sensing technologies:

Magnetic pickup sensors that detect gear teeth rotation

Optical encoders providing precise rotational position data

Accelerometers monitoring vibration levels and frequencies

Redundant sensor arrays ensuring system reliability

Wind turbine safety systems often include yaw control as a speed management tool:

Automatic nacelle positioning away from wind direction

Emergency yaw activation during overspeed conditions

Integration with meteorological sensors for predictive control

Manual override capabilities for maintenance scenarios

Pitch control systems serve as the primary defense mechanism against overspeed conditions in modern wind turbines. These sophisticated systems can adjust blade angles from their optimal power-generating position to a fully feathered position where blades present minimal wind resistance.

The most advanced turbines employ individual blade pitch control that offers several advantages:

Independent blade adjustment allows for precise load balancing

Rapid response times typically under two seconds for emergency stops

Continuous optimization maintains peak efficiency across wind speeds

Fault tolerance enables continued operation even with one blade system failure

Recognizing the critical importance of pitch control, manufacturers incorporate multiple backup systems:

Battery-powered emergency pitch systems that function during power outages

Spring-loaded failsafe mechanisms that automatically feather blades

Hydraulic backup systems providing reliable pitch control

Manual pitch override capabilities for maintenance and emergency situations

Modern pitch control systems integrate seamlessly with overall turbine control through:

Real-time communication with central control processors

Predictive algorithms that anticipate wind condition changes

Load monitoring systems that adjust pitch based on structural stress

Grid integration protocols that coordinate with electrical systems

Wind turbine braking systems provide the final layer of protection when aerodynamic controls cannot maintain safe operating speeds. These systems are designed as emergency measures rather than routine operational controls.

Wind turbine mechanical brakes typically employ disc brake technology similar to automotive applications but scaled for industrial use:

Disc brakes mounted on the generator or high-speed shaft

Hydraulically actuated calipers for precise control

Heat dissipation systems to manage energy during braking

Wear monitoring to ensure brake effectiveness

Some turbines incorporate braking systems on the low-speed rotor shaft:

Drum brake configurations suitable for high-torque applications

Multi-disc systems distributing braking force across multiple surfaces

Emergency locking mechanisms preventing rotor rotation during maintenance

The most effective braking approach combines mechanical systems with aerodynamic control:

Coordinated pitch and brake activation maximizes stopping effectiveness

Progressive braking sequences reduce mechanical stress

Emergency shutdown protocols that prioritize safety over equipment protection

Automatic brake release systems preventing brake drag during normal operation

Modern wind turbines may incorporate innovative braking approaches:

Electromagnetic brakes offering precise control without mechanical wear

Regenerative braking that converts kinetic energy back to electricity

Variable geometry systems that increase drag during emergency conditions

Smart braking algorithms that optimize stopping distance and component protection

Historical incidents demonstrate that overspeed conditions can indeed lead to catastrophic wind turbine failures. Understanding these risks highlights the critical importance of robust wind turbine emergency shutdown systems.

Overspeed-related failures typically manifest in several ways:

Centrifugal force can exceed blade root connection strength

Fatigue failures accelerated by excessive rotational stress

Ice loading combined with overspeed creating compound stress conditions

Manufacturing defects becoming critical under extreme conditions

Gearbox destruction from excessive input torque

Bearing seizure due to lubrication breakdown under extreme loads

Shaft failures when rotational energy exceeds material limits

Generator burnout from excessive electrical generation

Overspeed conditions create safety hazards that extend beyond equipment damage:

Blade throw incidents can endanger personnel and property within significant distances

Tower collapse may occur if structural limits are exceeded

Fire hazards from electrical system failures or mechanical friction

Ice throw scenarios where accumulated ice becomes projectile during overspeed conditions

Modern wind farms implement comprehensive risk mitigation approaches:

Multiple redundant protection systems ensuring fail-safe operation

Regular inspection protocols identifying potential failure modes

Advanced monitoring systems providing early warning of developing problems

Emergency response procedures minimizing consequences of system failures

Wind turbine safety systems must comply with stringent international standards:

IEC 61400 series standards governing wind turbine safety

Local building codes addressing structural and electrical safety

Environmental regulations limiting noise and visual impact

Grid connection standards ensuring electrical system compatibility

To effectively provide wind turbine overspeed protection, turbines must not only maintain ongoing maintenance but also undergo advanced monitoring systems to ensure proper operation over the turbines operational life.

Comprehensive maintenance programs address all aspects of overspeed protection:

Sensor calibration ensuring accurate speed and vibration monitoring

Brake system inspection maintaining mechanical brake effectiveness

Pitch system maintenance preserving aerodynamic control capabilities

Control system updates incorporating improved protection algorithms

Advanced monitoring systems provide continuous assessment of turbine health:

Vibration analysis detecting bearing wear and structural issues

Oil analysis monitoring gearbox and hydraulic system condition

Thermal imaging identifying electrical connection problems

Acoustic monitoring detecting abnormal operational sounds

Modern wind farms leverage big data analytics for improved maintenance planning:

Machine learning algorithms identifying patterns indicative of developing problems

Predictive failure models enabling proactive component replacement

Performance optimization maximizing energy production while maintaining safety

Remote monitoring capabilities reducing site visit requirements

Looking for safer and more reliable wind energy systems? Connect with KP Energy’s experts today.

The wind energy industry continues advancing turbine overspeed control technologies through innovative research and development initiatives.

The next-generation control systems will improve protection in the following ways:

Artificial intelligence integration enabling more sophisticated decision-making

Enhanced sensor fusion to enhance situational awareness using numerous data sources

Adaptive control algorithms that allow learning from experience while in operation

Wireless communication systems improving reliability and reducing installation costs

Ongoing materials research contributes to inherently safer turbine designs:

Carbon fiber blade construction offering improved strength-to-weight ratios

Advanced bearing technologies extending component life under extreme conditions

Smart materials that provide built-in monitoring capabilities

Modular designs facilitating easier maintenance and component replacement

Q1: What Is The Typical Overspeed Threshold For Wind Turbines?

Most modern wind turbines actuate their overspeed protection systems when rotor speed reaches 10–20% above the rated speed. For a typical utility-scale turbine (2 MW+) that operates at a nominal 12–16 RPM, the overspeed trip threshold would generally be set between 15 and 19 RPM. Smaller or older turbines spin faster and would have higher thresholds.

Q2: How Quickly Can Wind Turbine Braking Systems Stop A Spinning Rotor?

For wind turbines, the goal for emergency shutdowns is typically to stop the rotor in about 30-90 seconds, and there are variations based on both the wind and type of braking mechanism. The aerodynamic braking with pitch is usually faster stop and less fatigue on the drivetrain without pitch using mechanical braking.

Q3: Do All Wind Turbines Have The Same Type Of Overspeed Protection?

Wind turbine safety systems are differently employed based on turbine manufacturer and turbine size, and also different based on age of turbine. For example, older turbines utilized "mechanical" systems to stall or shut down the turbine, while a modern wind turbine uses an entirely different system of management that involves pitch control, electrical management and mechanical backup systems as part of a safety system.

Q4: What Weather Conditions Most Commonly Trigger Overspeed Protection?

Most turbine overspeed control systems have been engaged due to sudden wind gusts, unsettling wind direction changes, and strong thunderstorms. Wind shear or situations in which the velocity of wind at different heights, is highly variable can have an incredible influence on turbine operation.

Q5: How Often Do Overspeed Protection Systems Activate?

Usually, overspeed protection triggering for most well-maintained modern wind turbines is a rare event, generally occurring possibly, five times a year, mostly in extreme weather, however, for numerous reasons the triggering of the overspeed event relies on local environmental wind conditions, and the maintenance practices of the turbine operator.