The power of wind energy has been recognized for centuries as an efficient and sustainable alternative to generating energy from fossil fuels. With location being one of the most crucial factors in harnessing wind energy, its production in India is transforming the renewable energy landscape.

To produce wind energy in the most efficient method, the design of modern wind turbine technology is the biggest contributing factor, as it affects the speed and efficiency of the turbine, thereby affecting the final production of the wind energy.

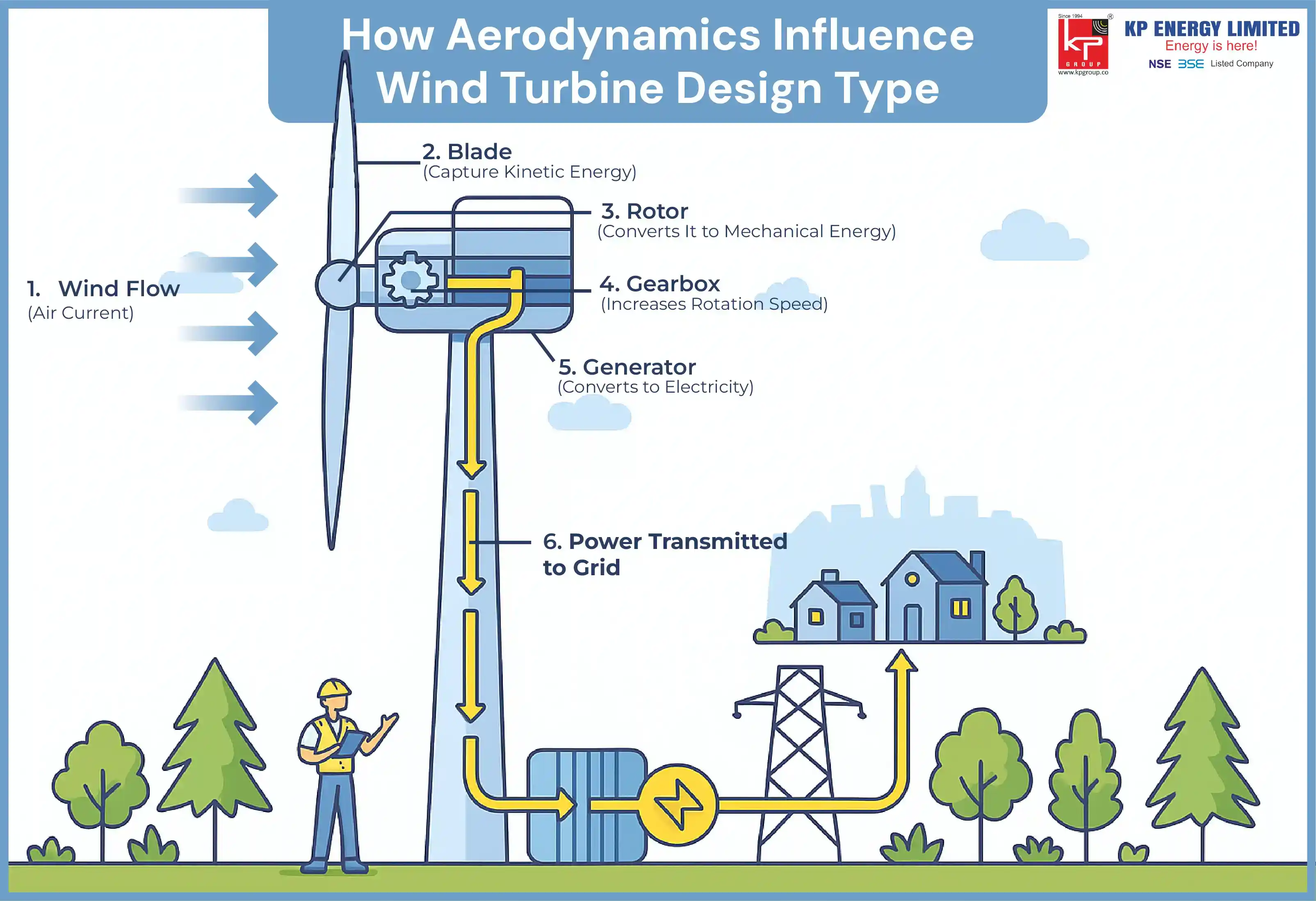

The science behind the production of wind energy is obtained from the force of wind. The production of wind energy in wind farms is possible due to the construction of large-scale wind farms, where the turbines capture the kinetic energy of the wind and further convert it into electricity.

When the air current flows, the wind turbine presents itself as an obstacle, thereby transforming the kinetic energy of the air current, slowing it down, and converting it into electrical energy. The entire process of transforming kinetic energy into electrical energy requires the optimization of the right kind of wind turbine blade design to ensure maximum efficiency and optimal yield.

Two-blade turbines: They are lighter and cost-effective but suffer from stability issues, higher vibration, and reduced efficiency in capturing wind energy.

Multi-blade turbines: They provide better torque at low wind speeds but face higher wind resistance, increased material costs, and reduced efficiency in power generation.

Three-blade turbines: strike the right balance between stability, efficiency, and cost. They minimize vibration, optimize aerodynamic performance, and deliver reliable power generation, making them the most widely adopted design in modern wind energy systems.

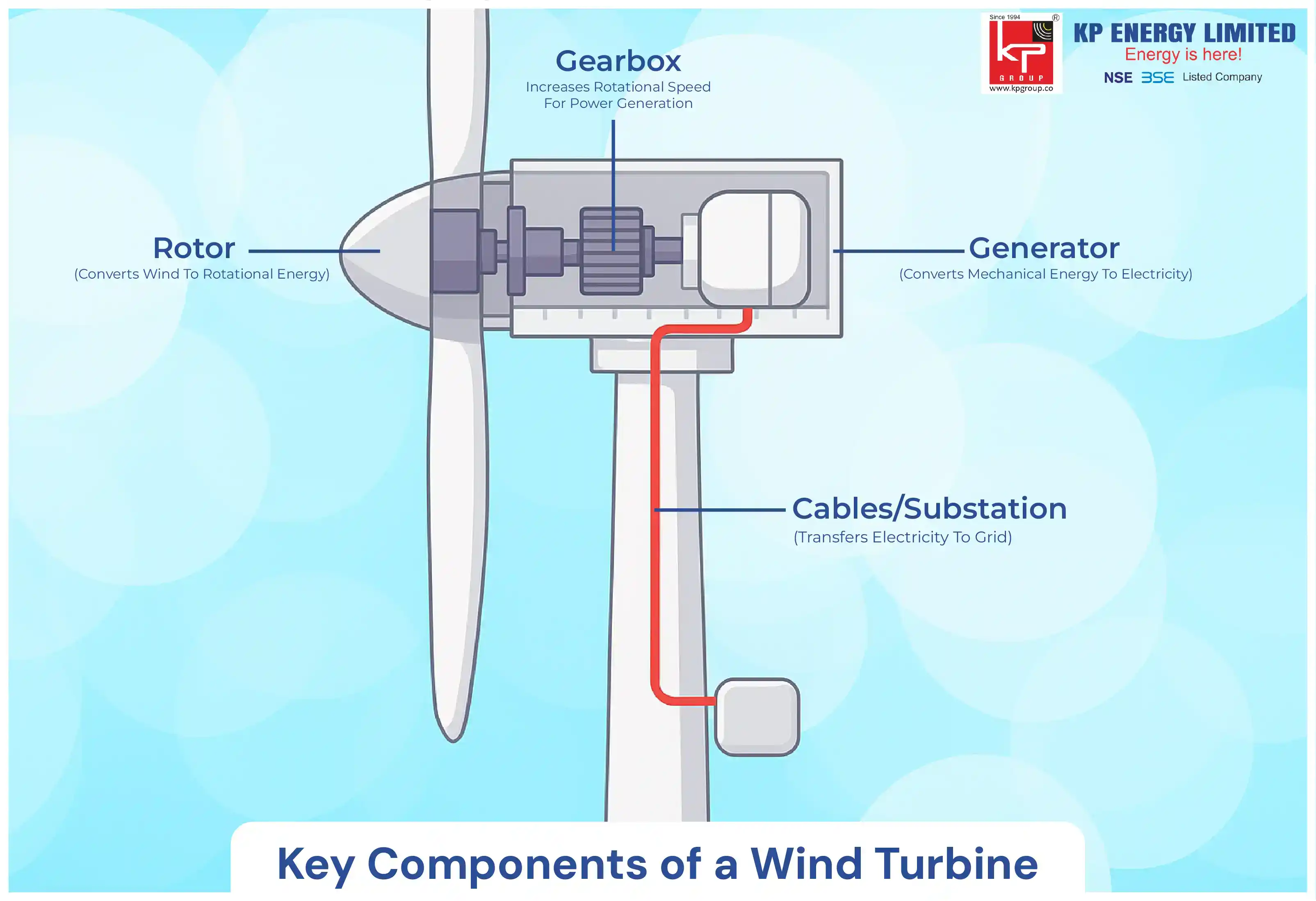

The Rotor, which is composed of the blades and the shaft that holds them together. The rotor converts the energy source of the turbine into mechanical rotational energy, which can be used to generate electricity.

The Gearbox, mounted on the shaft, the Gearbox serves to up-rotate the speed, a slow-turning turbine to a high-speed engine, the latter needed to generate power (electricity).

Each of these cables then carries electricity to the substation, from where it gets distributed to various homes, factories, public spaces, and so forth.

In most cases, where production of energy is the end outcome, the 3-blade design has been the most sought-after application, which was originally introduced as a compromise. Where running the turbine with one blade was considered a sufficient number. However, it would impose a great risk on the entire structure of the turbine, as it would be unbalanced and lose its stability in heavy winds.

On the other hand, a two-blade design would offer greater yield than that of a one-blade turbine, but would impose an additional set of risks, where there would be a higher chance of unbalanced torsional force at the center of the blade, causing a gyroscopic precession, which would result in wobbling and instability of the turbine, causing it to wear down and downgrade over time.

Four-blade or more would ideally produce maximum power that a turbine can generate for itself. However, it is not economically viable, would reduce the rotational speed, add extra weight to the turbine, and cost more to buy the additional blades. Hence, three blades are the most ideal number setup for optimal generation of wind energy on large-scale lands. As it allows for managing the high energy yield at the same time provide stability to the structure of the turbine.

The structure of the three-blade design is more stable and grounded. Its installation is relatively simple and it allows the turbine to perform at maximum capacity, without the hassle of vibrations or big turmoils. Aerodynamically, three blades allow for sufficient lift and wind energy capture while minimizing the turbulence, which would otherwise increase with more than three blades.

The manufacturing, transportation, and maintenance costs of a three-blade turbine are economical as compared to four or more blades, making the production cost much viable. Additionally, with more blades, there is an increased chance of complexities arising in different blades, which would require frequent inspection and repairs.

While a two-blade turbine makes the turbine weight less, it is not designed to capture the energy efficiency of a three-blade turbine. The main objective of a well-designed turbine is to capture the maximum energy from the wind. According to the Betz Limit, no wind turbine can capture more than 59.3% of the kinetic energy in the wind. Hence, choosing three blades makes the aerodynamics best for the wind conditions, leading to potentially increased energy output in high-wind situations.

Tip speed ratio and optimal TSR values: Tip speed ratio is the ratio of the speed of the turbine blade to the wind speed. For a three-blade turbine, the ideal ratio is 7; however, anywhere between 6 to 8 is considered to be a good number. A well-designed turbine with the proper ratio maximises the amount of energy harnessed from the wind and converted to electrical energy by its generator.

While manufacturing considerations between Carbon fiber vs. fiberglass materials are required, as it directly impacts the functioning and output levels, wind turbines can be made from both carbon fiber as well as glass fiber. There are various factors that influence this decision. While more expensive to produce, carbon fibre blades are stronger, stiffer, and much lighter than glass fibre blades. These characteristics allow larger blades to be produced, which in turn makes them more efficient. However, due to the increased costs, carbon fibre blades are generally used in offshore applications where much larger wind turbines are situated.

According to aerodynamics, Betz's law indicates the maximum power that can be extracted from the wind, irrespective of the design of the wind turbine. The law states that a maximum of 59.3% is the amount of kinetic energy from the wind that a turbine can extract and convert into usable power.

The choice between two-three-four or more blades depends on a lot of factors, including the budget for the project, environmental limitations, nature of wind flow, topical conditions, and land type. The final decision should always be based on the objective one has to accomplish in the long run. At a time when industrialization is at its peak, the choice to generate energy through wind energy is allowing industries to stay ahead of the curve, giving them a competitive edge.

KP Energy, a leading producer of renewable energy, navigates complex landscapes, streamlining the entire process of wind, solar, and hybrid development with precision and ahead-of-time completion.

Q1: What are the main advantages of wind energy

Clean source of energy generation, cheaper than utilizing fossil fuels as a source of raw material to produce energy, self self-reliant method of procuring energy.

Q2: How many blades are the most ideal for generating energy through wind energy?

Three blades are considered to be the ideal number for securing higher efficiency, staying cost-effective, reducing vibration, and overall improved performance.